What are the usage scenarios of DC combiner box and AC combiner box? Which one is generally used in photovoltaic power plants?

What are the usage scenarios of DC combiner box and AC combiner box? Which one is generally used in photovoltaic power plants?

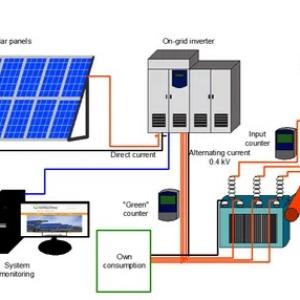

Both types of combiner boxes may be used in photovoltaic power stations, which are related to the system structure of the power station.

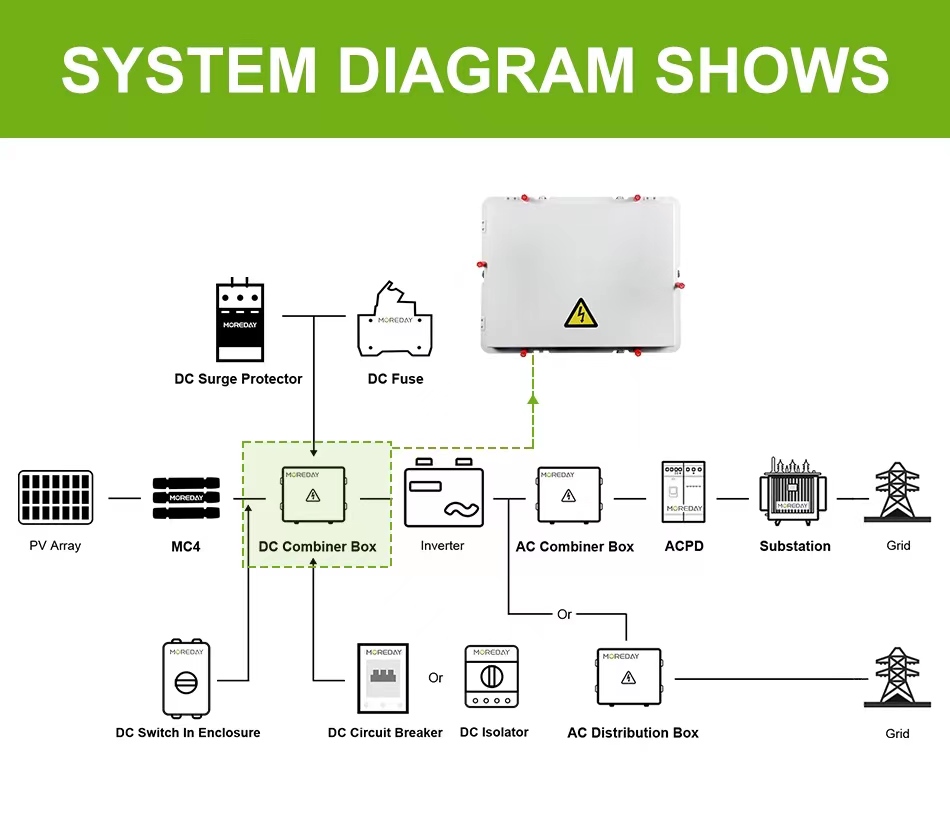

1. DC combiner box

In order to reduce the impact on the grid and avoid damage to the inverter due to excessive voltage, multiple parallel connections are usually used to collect multiple DC currents from the solar array to the input of the inverter. According to the DC voltage range of the inverter input, a certain numb

er of photovoltaic modules of the same specification are connected in series to form a series of photovoltaic modules, and then several series are connected to the lightning protection combiner box of the photovoltaic array, and the output is output through the lightning protector and circuit breaker, so as to facilitate the access of the post-inverter.

2. AC combiner box

A photovoltaic power generation system consisting of a string inverter, which is installed between the AC output side of the inverter and the grid connection point/load. It is equipped with input circuit breaker, output circuit breaker, AC lightning protector, and optional intelligent monitoring instrument (monitoring system voltage, current, power, electric energy and other signals). Its main function: to combine the output current of multiple inverters, and at the same time protect the inverter from the hazards from the AC grid-connected side/load, as the output disconnection point of the inverter, improve the safety of the system, and protect the safety of installation and maintenance personnel.

In photovoltaic power generation systems, combiner boxes play a crucial role. This article will focus on the working principle, main functions, operation and maintenance management of the combiner box, so that you can re-understand its simple side.

How the combiner box works

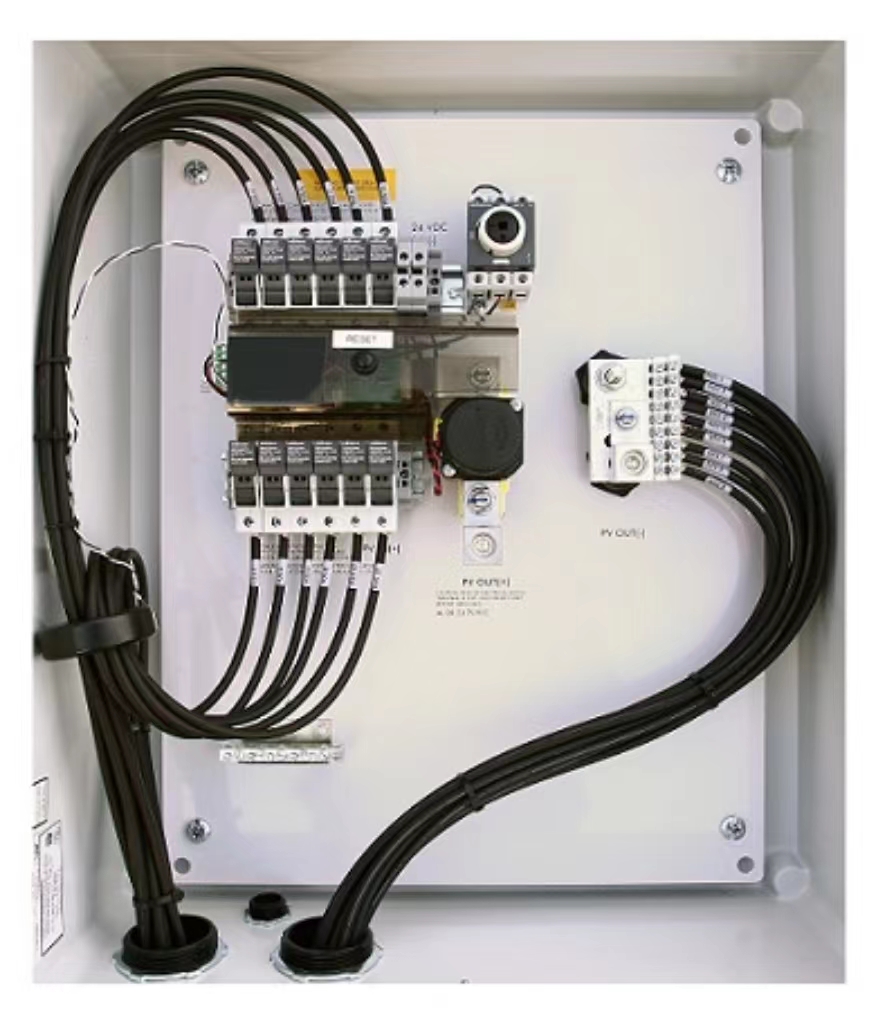

The working principle of the combiner box mainly involves the connection and protection of the circuit. When photovoltaic modules generate direct current, they are connected via cables to the input port of the combiner box. The circuitry inside the combiner box will combine and distribute this DC power, and then output the pooled DC power to the inverter or other equipment. In the process of combining, the combiner box will monitor the current, voltage and power parameters of each photovoltaic series, and realize the functions of short circuit protection, anti-reverse connection protection, and overcurrent protection through the protection device.

The main function of the combiner box

The combiner box is an important part of the photovoltaic power generation system, and its main function is to combine and distribute the direct current generated by the photovoltaic modules for subsequent connection to the inverter or other equipment. The combiner box is usually installed underneath the PV module and is connected to the PV module by cable.

Combiner function:The combiner box can connect the direct current generated by multiple photovoltaic modules in series to form a large voltage output. This increases the voltage level of the system, reduces current loss, and thus increases the efficiency of the system.

Monitoring function: The combiner box can monitor the current, voltage and power parameters of each PV series in real time. Through the monitoring of these parameters, we can detect faults or abnormalities of PV modules in time to ensure the normal operation of the system.

Lightning protection function: In the combiner box, lightning protection devices are usually installed, such as lightning arresters or surge protectors. These devices can effectively prevent lightning strikes from damaging the photovoltaic power generation system and protect the safety of the system.

Short-circuit protection function: The combiner box also has short-circuit protection function. When a short-circuit fault occurs in the PV series, the combiner box will automatically cut off the connection with the faulty series to avoid the expansion of the fault and protect the safety of the whole system.

Anti-reverse polarity protection function: In order to prevent the positive and negative poles of photovoltaic modules from being reversed, the combiner box is usually equipped with an anti-reverse polarity protection device. In this way, equipment damage and safety accidents caused by connection can be avoided.

Over-current protection function: The combiner box can also be set with over-current protection function. When the current in the PV series exceeds the set value, the combiner box will automatically cut off the current to protect the PV modules and related equipment from damage.

Communication function: Some advanced combiner boxes also have communication functions, which can be connected with monitoring systems or data acquisition systems to achieve remote monitoring and control.

O&M management of combiner boxes

Regular inspection and maintenance

Regular inspection of the combiner box is the basis of O&M management. The inspection includes, but is not limited to:

Clean the combiner box: Keep the inside and outside of the combiner box clean to prevent the accumulation of dust and debris that can affect the heat dissipation effect.

Check the cable connection: Make sure the cable connection is secure and not loose or corroded.

Check the lightning protection device: Check if the lightning arrester or surge protector is working properly.

Check circuit breakers and fuses: Ensure that circuit breakers and fuses are in normal working condition, and replace them in time if necessary.

Check the monitoring system: Check the monitoring system of the combiner box to ensure that the data collection is accurate and the transmission is normal.

Data monitoring and analysis

The operation and maintenance management of the combiner box is inseparable from the monitoring and analysis of data. By monitoring the current, voltage, power and other parameters of the combiner box in real time, potential problems can be found in time. At the same time, the analysis of the data can evaluate the operation status of the combiner box and provide a basis for optimizing the system. For example, by analyzing the data, we can find the imbalance of the PV series and make timely adjustments to improve the power generation efficiency of the system.

Fault diagnosis and troubleshooting

During the operation of the combiner box, various faults may occur. Timely and accurate fault diagnosis and troubleshooting is an important task of O&M management. Common faults include cable faults, circuit breaker tripping, lightning protection device failure, etc. For some common failures, they can be prevented through regular inspection and maintenance. For sudden failures, it is necessary to have the ability to respond quickly and deal with them, and restore the normal operation of the system in a timely manner.

Personnel training and safety management

The professional knowledge and skills of O&M personnel are crucial to the O&M management of combiner boxes. Organize regular personnel training to improve the technical level and troubleshooting ability of operation and maintenance personnel. At the same time, strengthen safety management to ensure that operation and maintenance personnel follow relevant safety regulations when operating the combiner box to prevent accidents.

Document management

Perfect document management is of great significance for the operation and maintenance management of combiner boxes. The document should include information such as the installation, commissioning, and operation and maintenance records of the combiner box. These documents not only help with troubleshooting and maintenance, but also provide a reference for system optimization and upgrades.

In general, as an important part of the photovoltaic power generation system, the combiner box undertakes a variety of functions such as confluence, monitoring, lightning protection, and short-circuit protection. Through reasonable operation and maintenance management, the normal operation of the combiner box can be ensured, and the efficiency and stability of the photovoltaic power generation system can be improved. In the future, with the continuous development of photovoltaic technology, the combiner box will continue to innovate and upgrade to provide more reliable support for the development of photovoltaic power generation system.