Can not be ignored photovoltaic connectors - small devices, large role

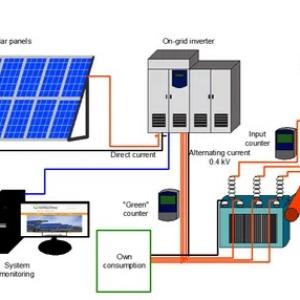

Can not be ignored photovoltaic connectors - small devices, large roleWith the wide application of photovoltaic power generation, the connection between photovoltaic modules and module strings, the DC connection of combiner boxes, inverters and other equipment are widely used in the international standard MC4/H4 connectors.

1. Performance requirements of photovoltaic connectors

So what are the performance requirements of photovoltaic connectors?

First, the photovoltaic connector should have good conductivity, and the contact resistance should not be greater than 0.35 milliohms.

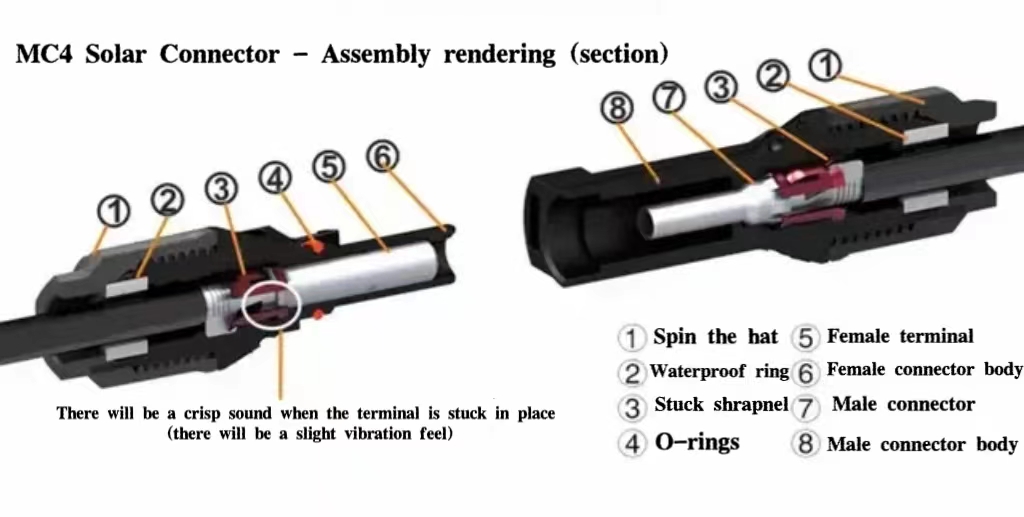

Second, it needs to have sufficient safety performance, So as to ensure the safety performance of solar modules. The environment and climate used by solar energy equipment are sometimes in very harsh weather and environment, so it should have waterproof, high-temperature, anti-corrosion, high insulation and other properties, and the protection level should reach IP68.

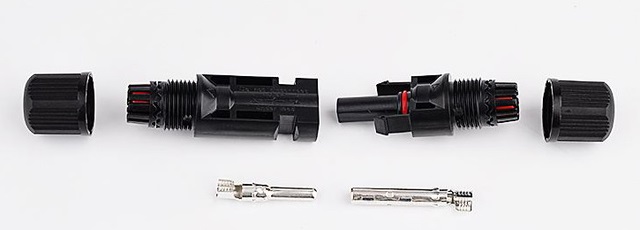

Third, the structure of the solar connector should be firm and reliable, and the connection force of the male and female connectors should not be less than 80N. For MC4 connectors connected to 4 mm² cables, the temperature must not exceed the upper limit temperature of 105 degrees Celsius when carrying a current of 39 A. MC4/H4 connector is a single-core connector, divided into male and female, with good sealing, convenient plugging, easy maintenance, easy maintenance and many other advantages.

2. Precautions for installation of photovoltaic connectors

The purchase of plug should pay attention to product quality, including the size compliance of the internal metal conductor, the material thickness, elasticity and plating should meet the ability to carry large currents and good contact, and the plastic of the plug shell should ensure that the surface is smooth and free of cracks, and the interface is well sealed. When installing the component connector, it is necessary to avoid sun exposure and rain, so as not to cause aging of joints, corrosion of internal joints and cables, increase of contact resistance, and even ignition, resulting in a decrease in system efficiency or fire accidents.

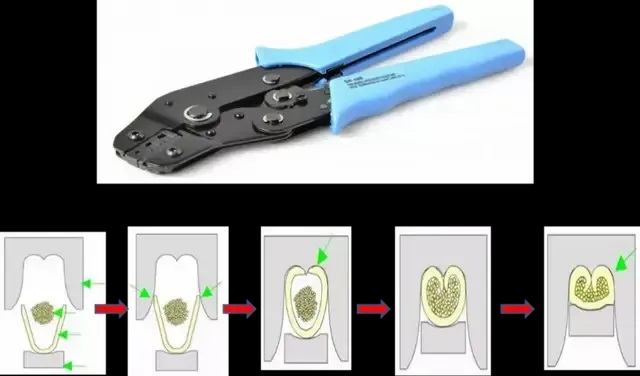

For the installation of photovoltaic connectors, the crimping link is the top priority, and professional crimping tools should be used. Before the construction of the photovoltaic power station, the relevant engineering installers should be trained in crimping operation.

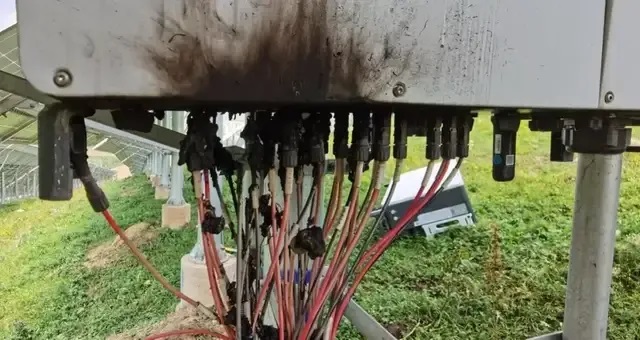

With the development of photovoltaic cell technology, the capacity of a single photovoltaic module is also increasing, and the string current is gradually increasing, although theoretically the design carrying current of MC4/H4 connector is enough to meet the requirements of these large-capacity components, but due to various reasons, in recent years, many photovoltaic power stations have more and more connectors melted, burned and even led to combiner boxes, inverter burning accidents.

As we all know, there are usually 600-1000 such connectors in a 100kWp scale photovoltaic power station, and their contact resistance and other working conditions are very important for the normal operation of photovoltaic power stations. The poor working condition of the connector will affect the increase of internal resistance on the DC side, resulting in the decrease of power generation efficiency of the power station, and the heating or even burning of the connector due to poor contact, which will lead to the burning of the combiner box and inverter, and even lead to the occurrence of large-scale fires.

Summary: Component connectors, connector inserts connected to combiner boxes and string inverters are where failures are frequent. Although the connector is small, it is very important in the photovoltaic power generation system, especially in the operation and maintenance process after the completion of the power station, it is necessary to pay attention to its operation status, and regularly check the heating phenomenon of the connection plug to ensure that there is no abnormality and normal operation.